Overview

A large warehouse handles hundreds of inbound and outbound truck shipment every day. Even though operations inside a warehouse are highly streamlined and optimized, operations at the loading dock still remain a bottleneck to efficient movement of freight into and out of a warehouse.

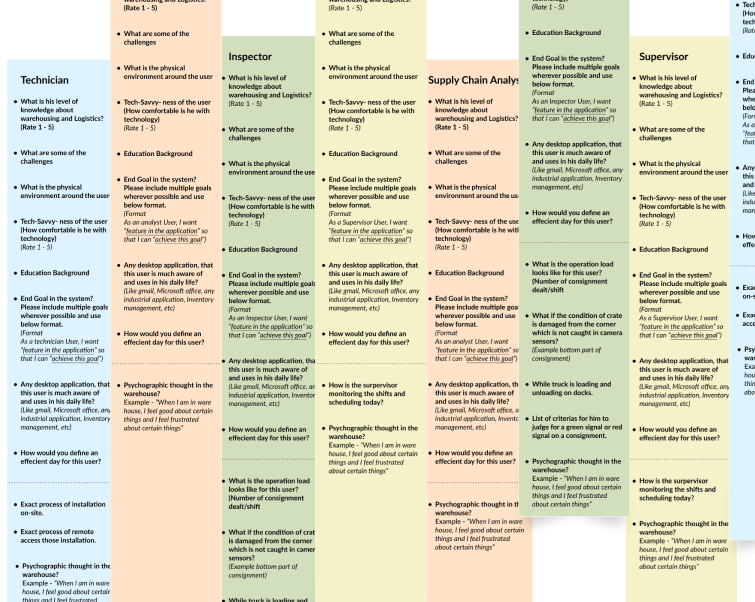

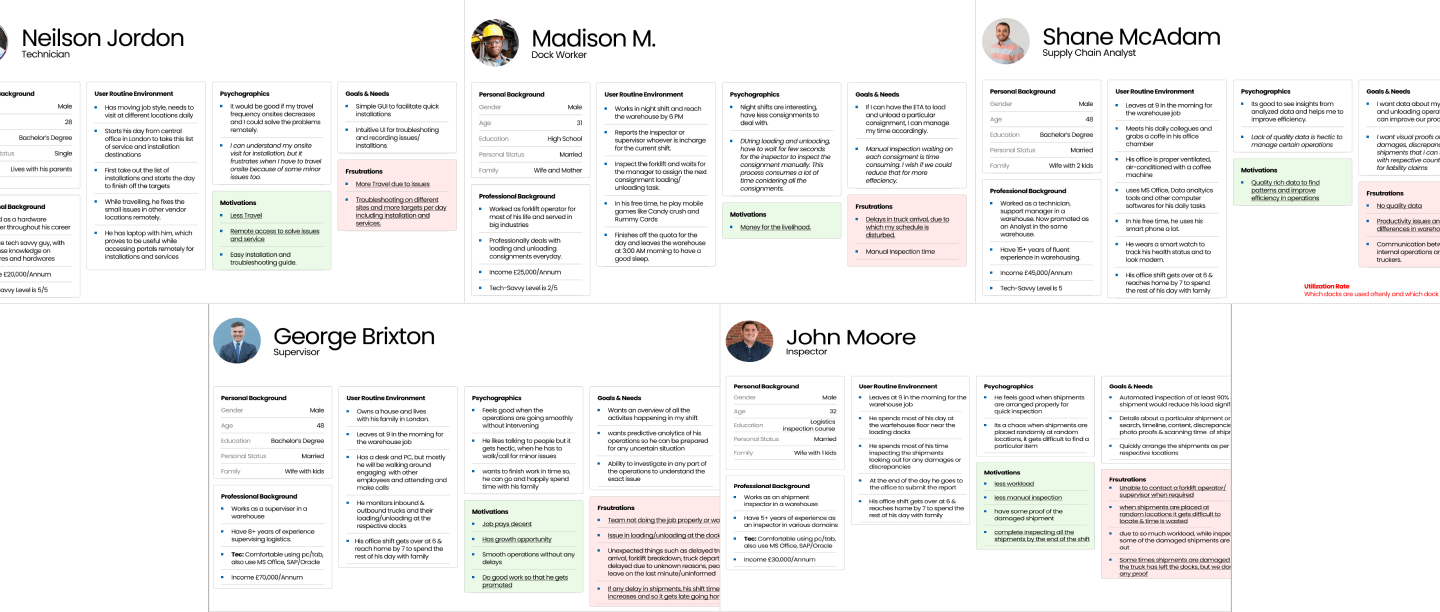

Interviewing the stakeholders & users

Investigating the possible loopholes /limitations/feasibilities

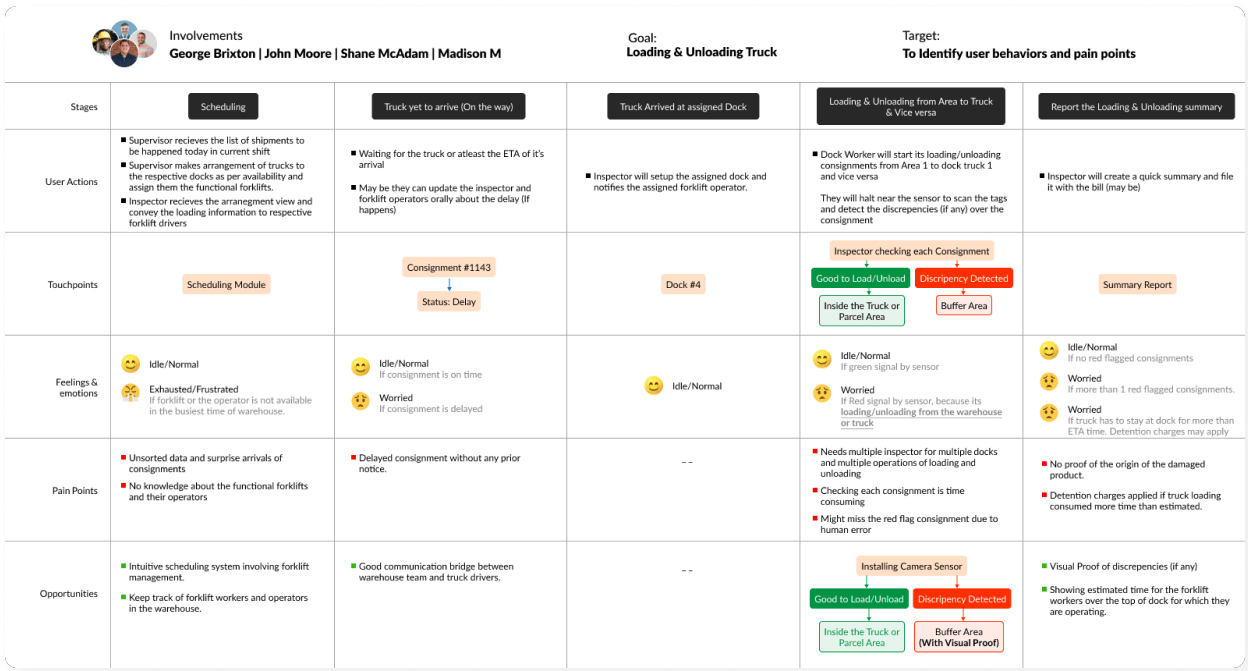

Identifying the user journey, product lifecycle & touchpoint

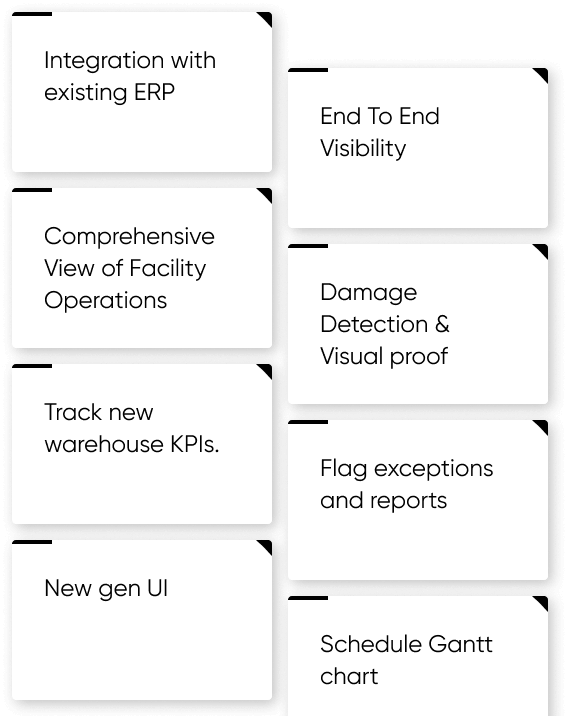

Feature benchmarking & competitor analysis

Ideating & prototyping designs and getting feedback

DockSight is an automated system that uses sensor towers to automatically scan all inbound and outbound freight right at the dock and automatically verify the contents and also check for possible damages. It can:

Challenge #1

Manual scanning, verification and validation of all inbound and outbound freight at the loading dock is time-consuming and a major reason for high Truck Turn-Around-Times and detention charges.

Challenge #2

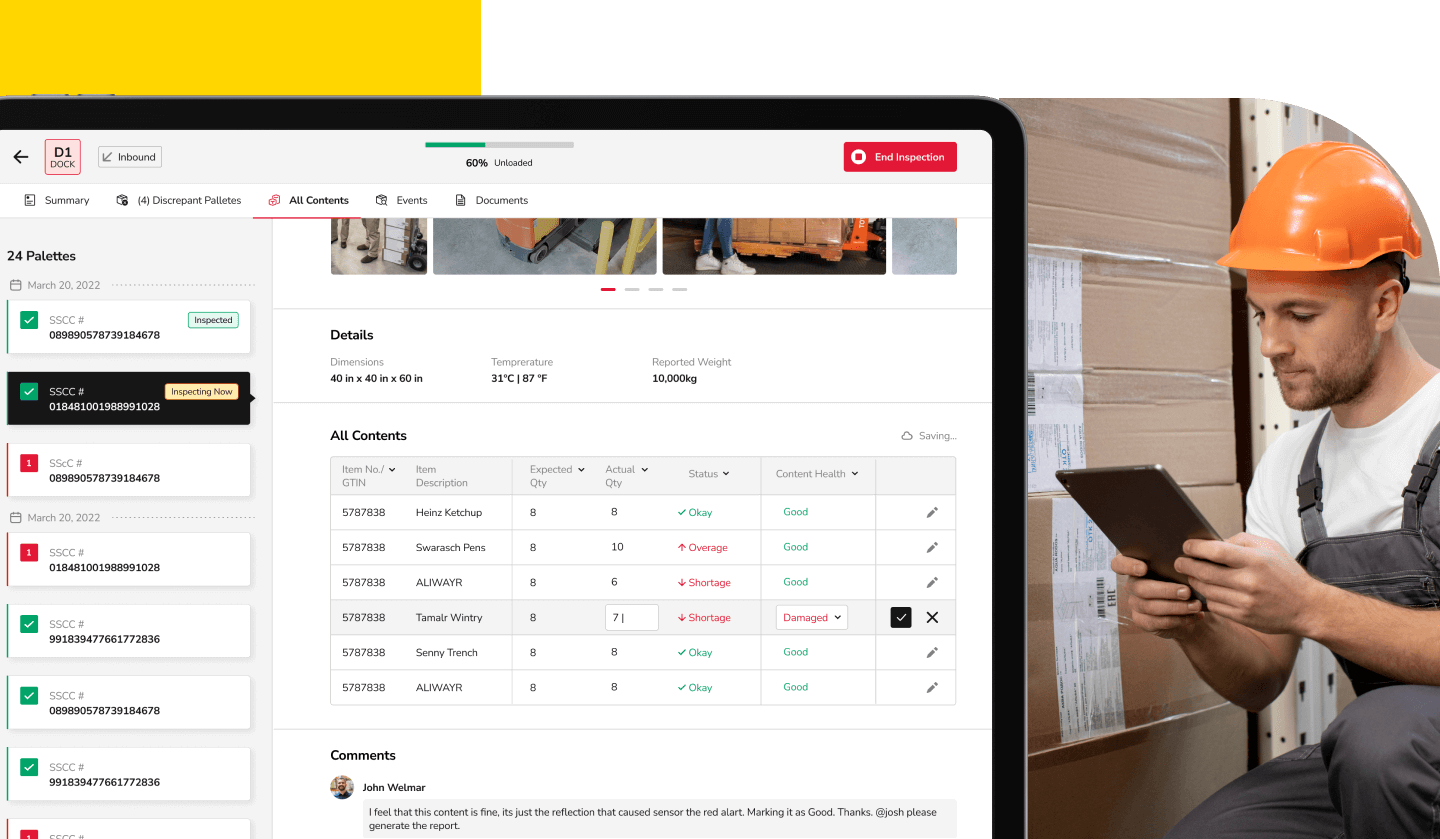

Mistakes in manual verification and unnoticed damages lead to expensive freight claim liabilities. There is an urgent need for an system that can scan all inbound and outbound freight and verify it automatically.

Transforming Warehouse Heroes

All had their own stories to tell. be it real-time data sync, discrepancies, supply chain monitoring or shipment delays

Uncovering Warehouse Management Challenges.

Manual inspection eats up a lot of man force, resulting in unproductively.

No proof of damaged shipment origin

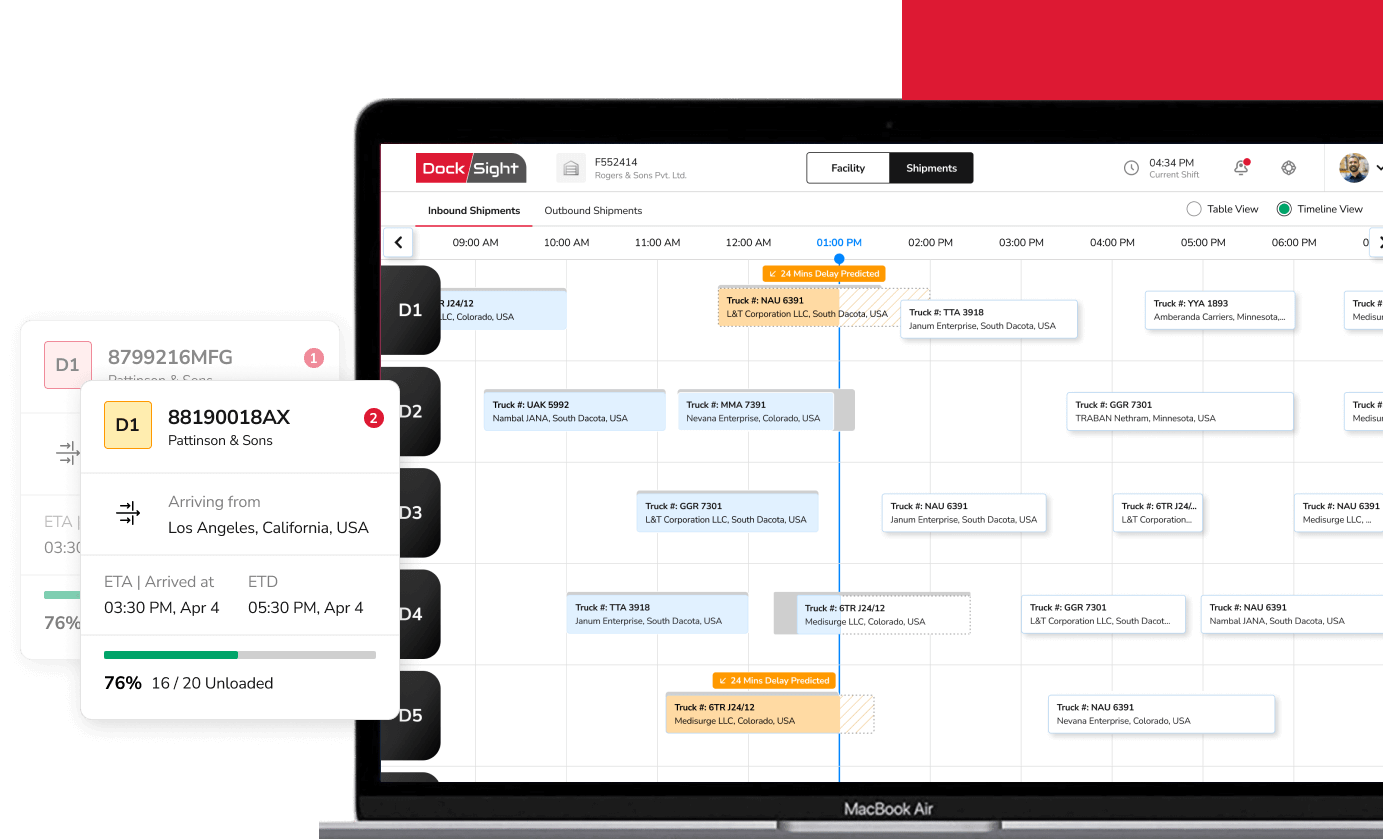

Shipment arrival delays, causing glitch in the schedules.

Missed discrepant objects due to human error

Lack of Quality Data to improvise the warehouse effeciency.

Deciphering

the Competition's

Moves

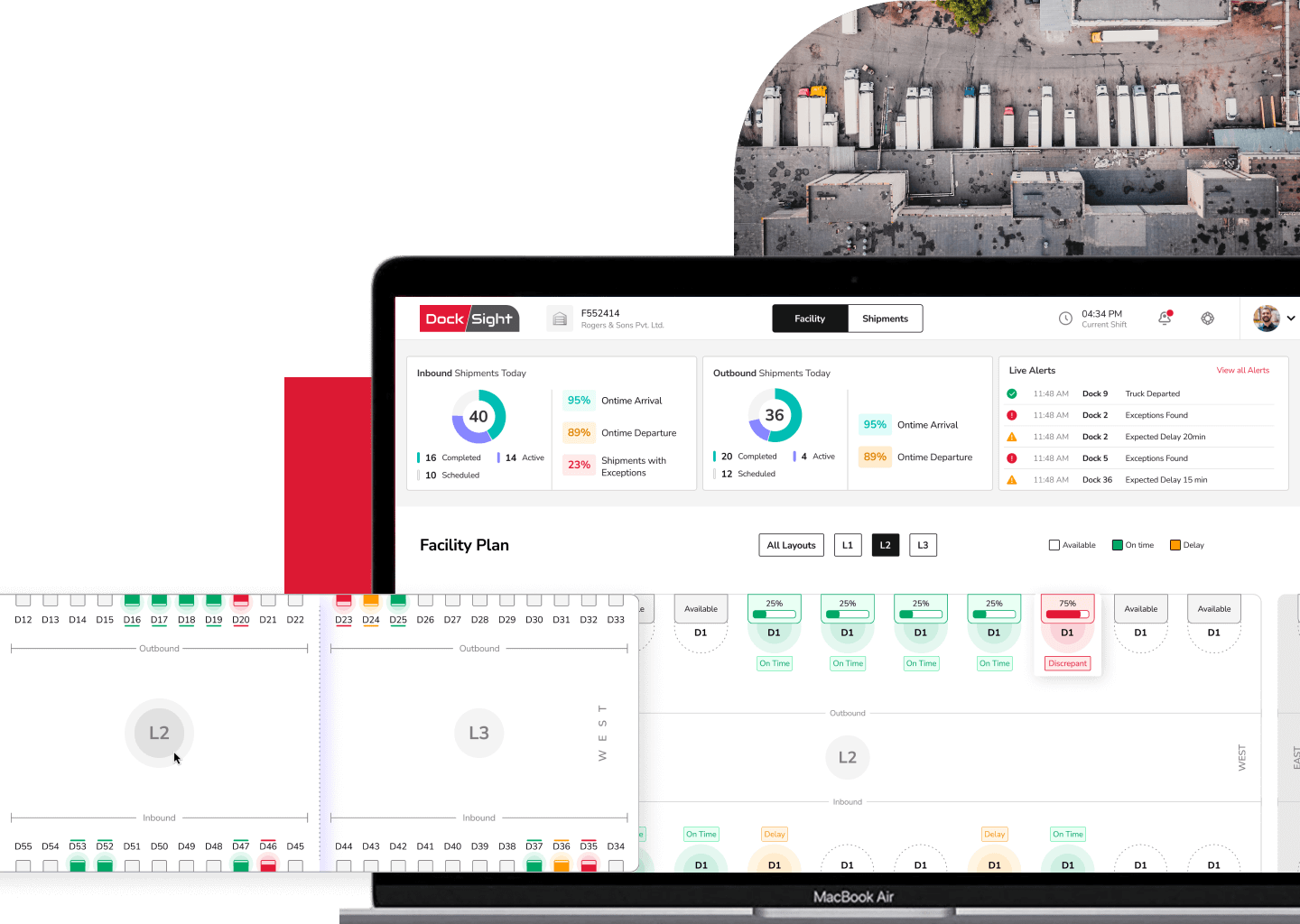

Birdview of the facility

Get a holistic perspective of your warehouse with the intuitive bird's-eye view, simplifying complex logistics at a glance.

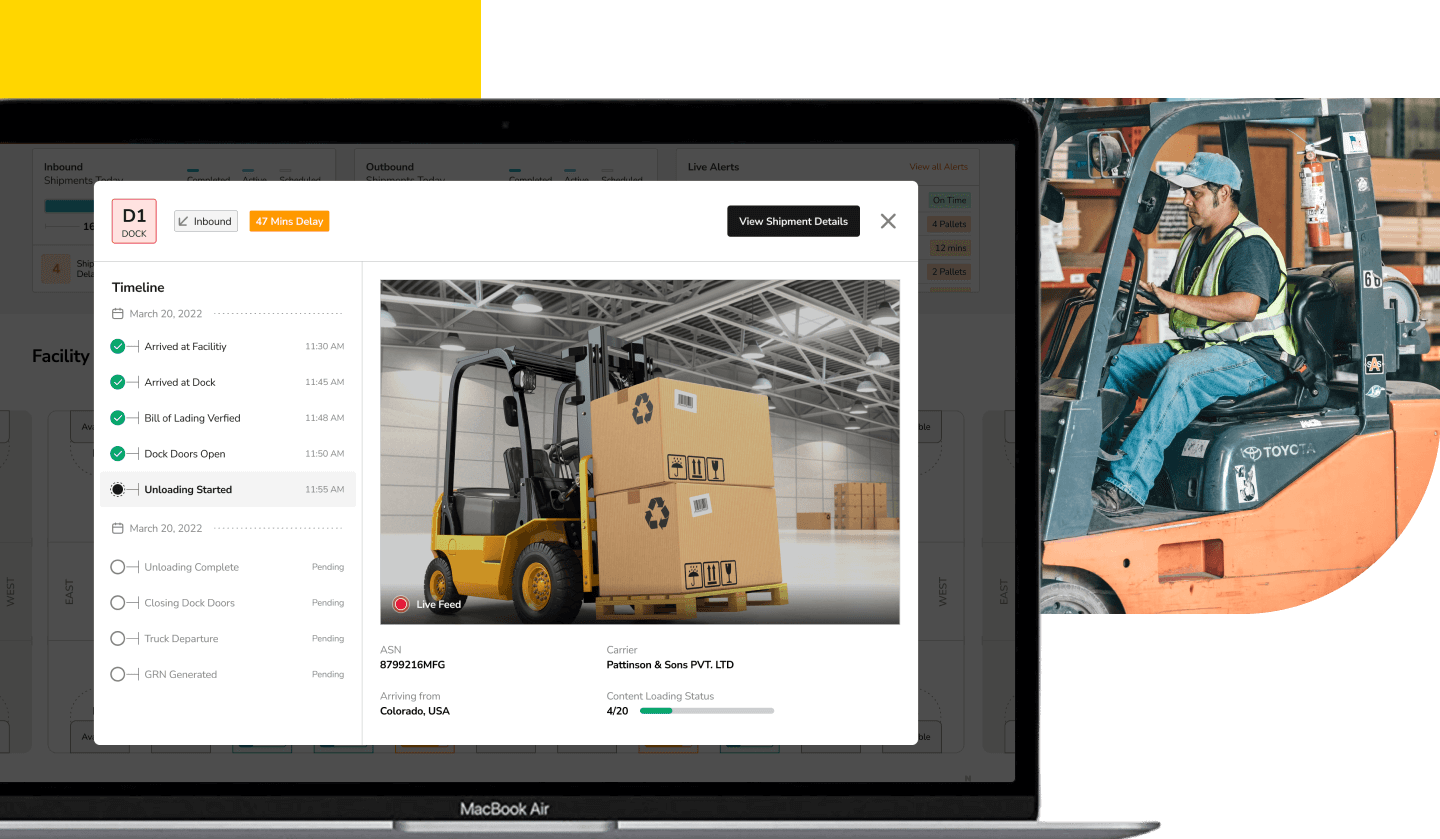

Shipment Timepunch

Get a holistic Efficiently track shipment time with precision and ease

Upcoming Shipments

Streamlining the shipment schedules with precision using a gantt chart view.

Track & Record shipments

Precise Discrepancy tracking made easy and hassle-free.

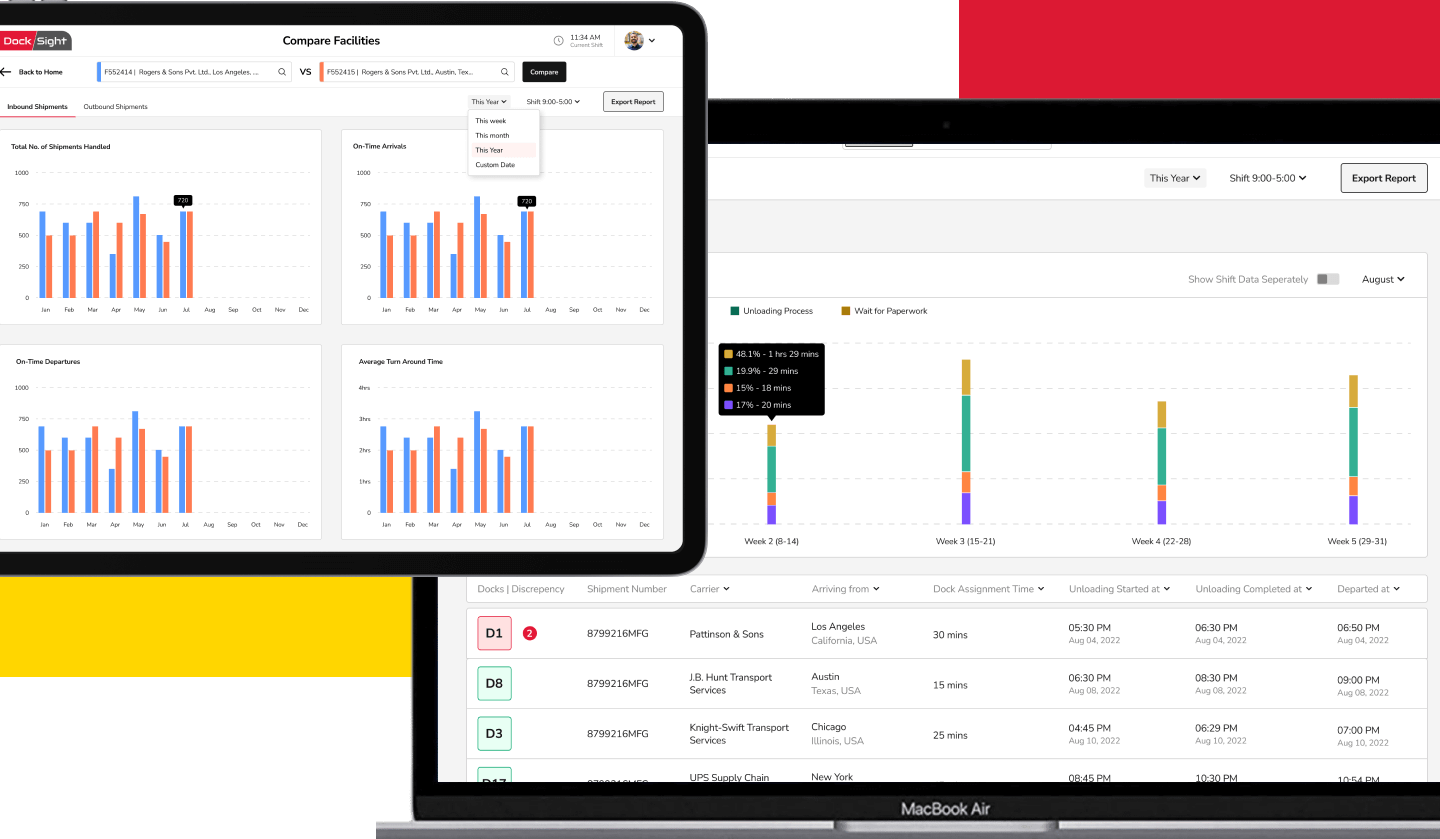

Compare Facility

Make informed decisions by comparing regional warehouse performance to improve functions & operations.

Share Dock Performance

Facilitate seamless data sharing with supply chain analysts.

A Beacon of Transformation in the Shadows.

Flag all overages, shortages & damages in inbound freight

Flag mis-shipments in outbound freight

Automatically generate ASNs and GRNs

Provide visual proof of material condition to support freight claims

Real-time visibility into dock operations across the facility

Analytics of dock operations to improve productivity

40%

Reduced truck turn-around Time by upto 40%

28.4%

Reduced shipping & receiving costs

100+

Facilities installed with Docksight

The product is still under development and is going through a round of user testings. As they say...

A good piece of art is never done. It's an iteration.

Start Your Journey with Us

Schedule a Meeting