Overview

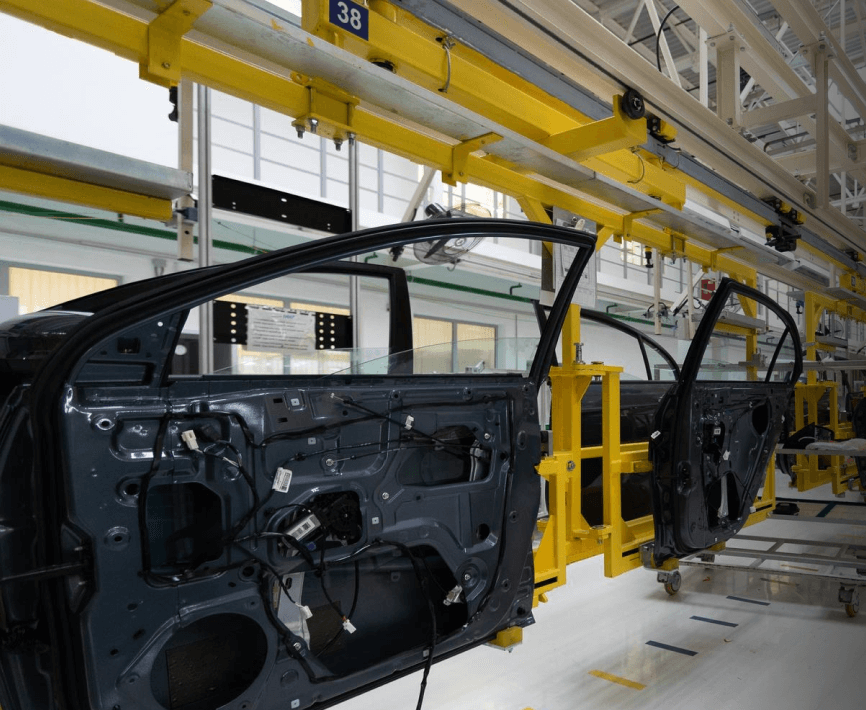

In the realm of manufacturing excellence, precision and quality are paramount. Welcome to the world of "LineSense," where we've redefined the assembly line landscape.

In this transformative project, we've harnessed the power of advanced technology, leveraging the combination of cameras and sensors to infuse artificial intelligence into most of the step of the manufacturing journey.

Setup

For an instance, consider the product Mahindra Scorpio Petrol Variant

The journey unfolded for our heroes.

Story

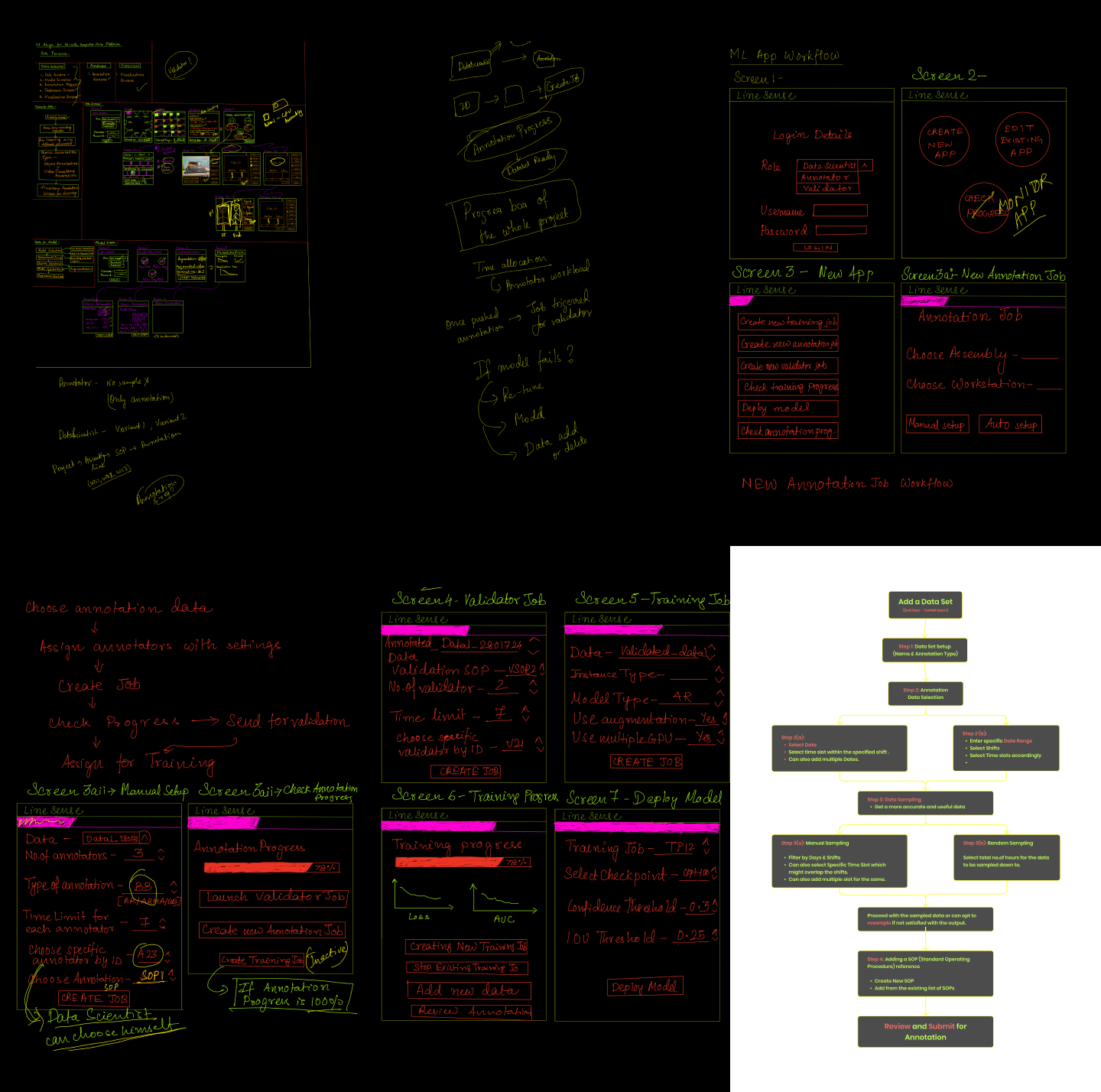

1.

Create Data set.

2.

Annotate agents and actions.

3.

Validate annotated data.

4.

Develop training model.

5.

Test & deploy model

BUSINESS GOALS

The project aims to enhance manufacturing efficiency, improve product quality, reduce operational costs, and achieve scalability and adaptability in assembly line operations.

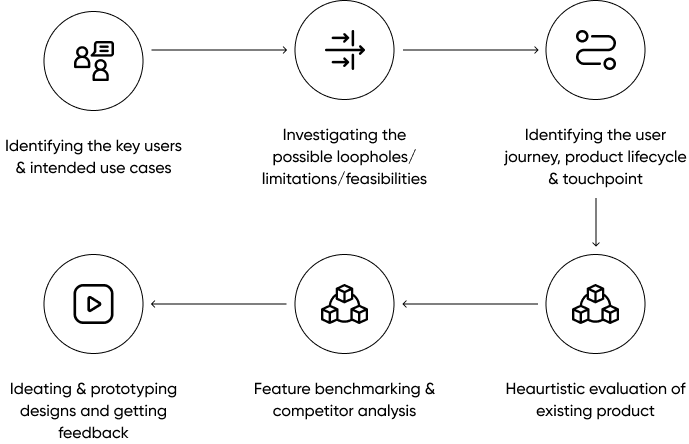

APPROACH

Meet the heroes of our product.

Maria Nicolas

32, Female

Alicia holds a master's degree in data science and has several years of experience in machine learning and computer vision. She is passionate about harnessing AI to solve real-world problems.

Ensuring the quality and diversity of training data, Collaborating effectively with annotators and validators.

Efficient dataset creation, Improving AI model accuracy, Successfully implementing AI solutions to enhance manufacturing.

James Nortan

28, Male

James has a background in computer science and is skilled in image annotation. He has experience in accurately labeling data for AI model training.

Maintaining annotation accuracy and consistency, Collaborating effectively within the team and the only source of truth to refer in case of complex labels/annotation.

Providing high-quality annotations, Supporting data scientists in developing accurate AI models, Contributing to the improvement of manufacturing processes.

Synchronised operations for seamless progress.

workflow

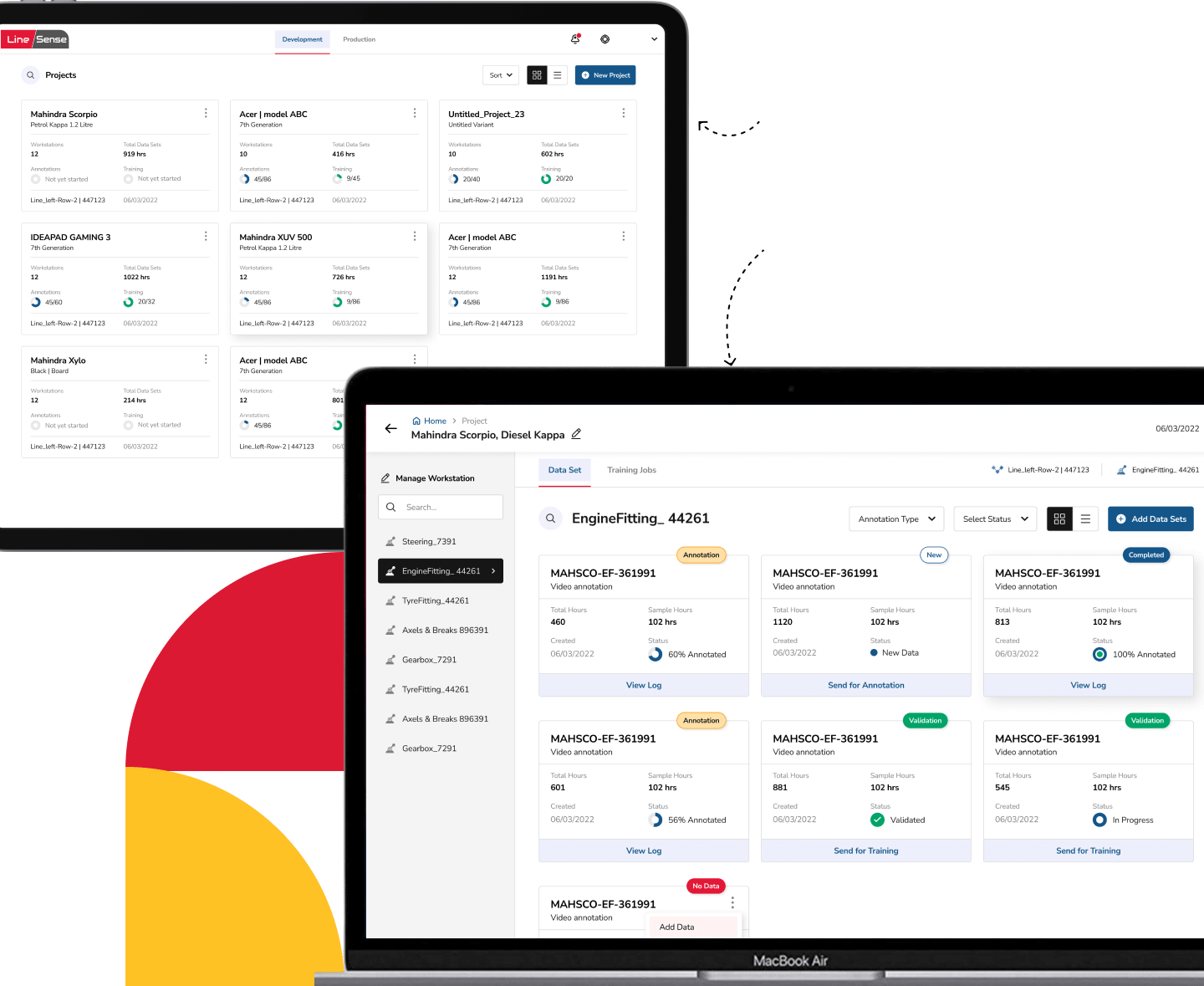

Project & Dataset

Each card on left represents a product/project that has to go under an assembly line.

Each card below represents the video data sets to be annotated.

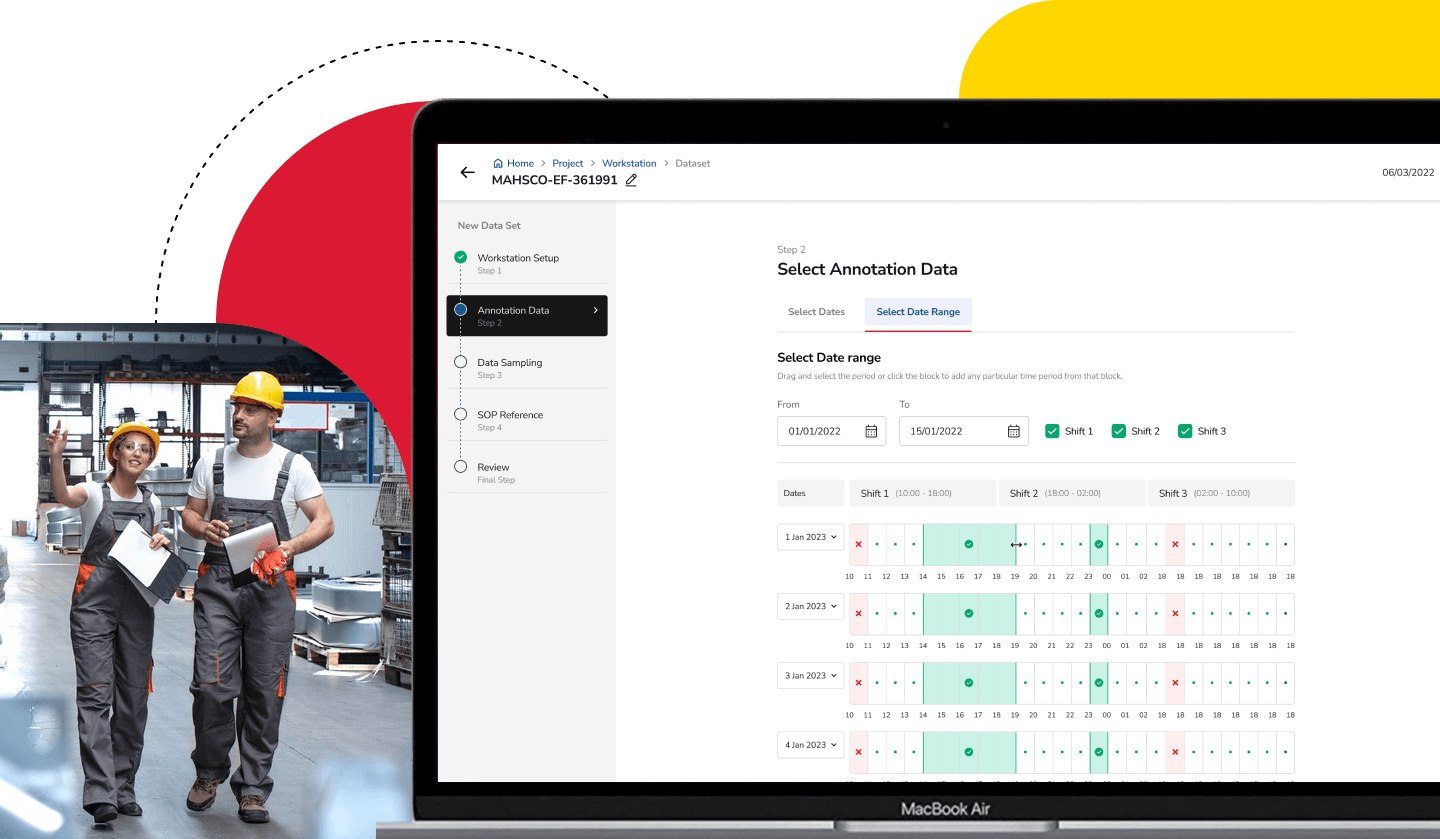

Data Sampling

AI precision: Automated video sampling simplified.

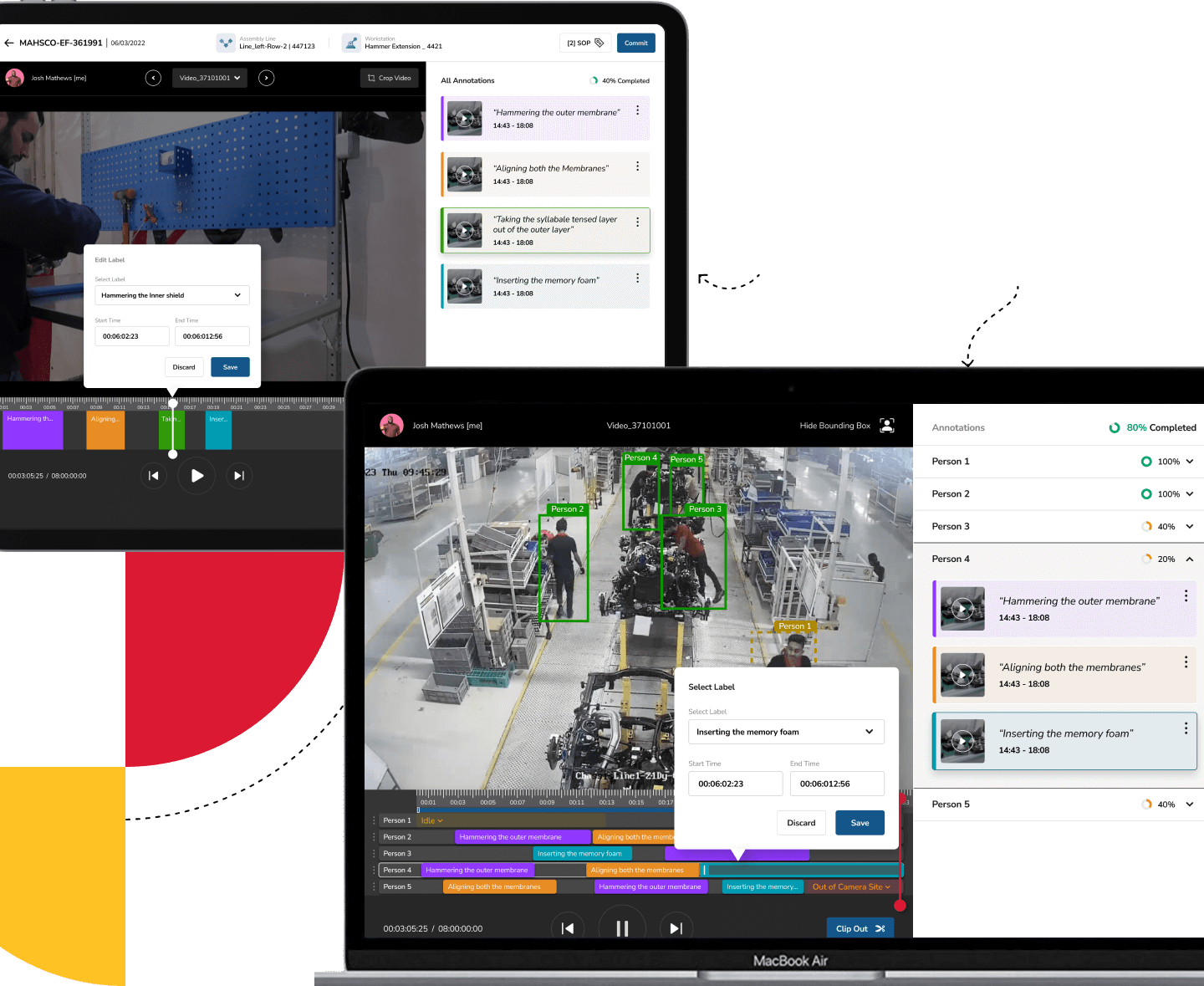

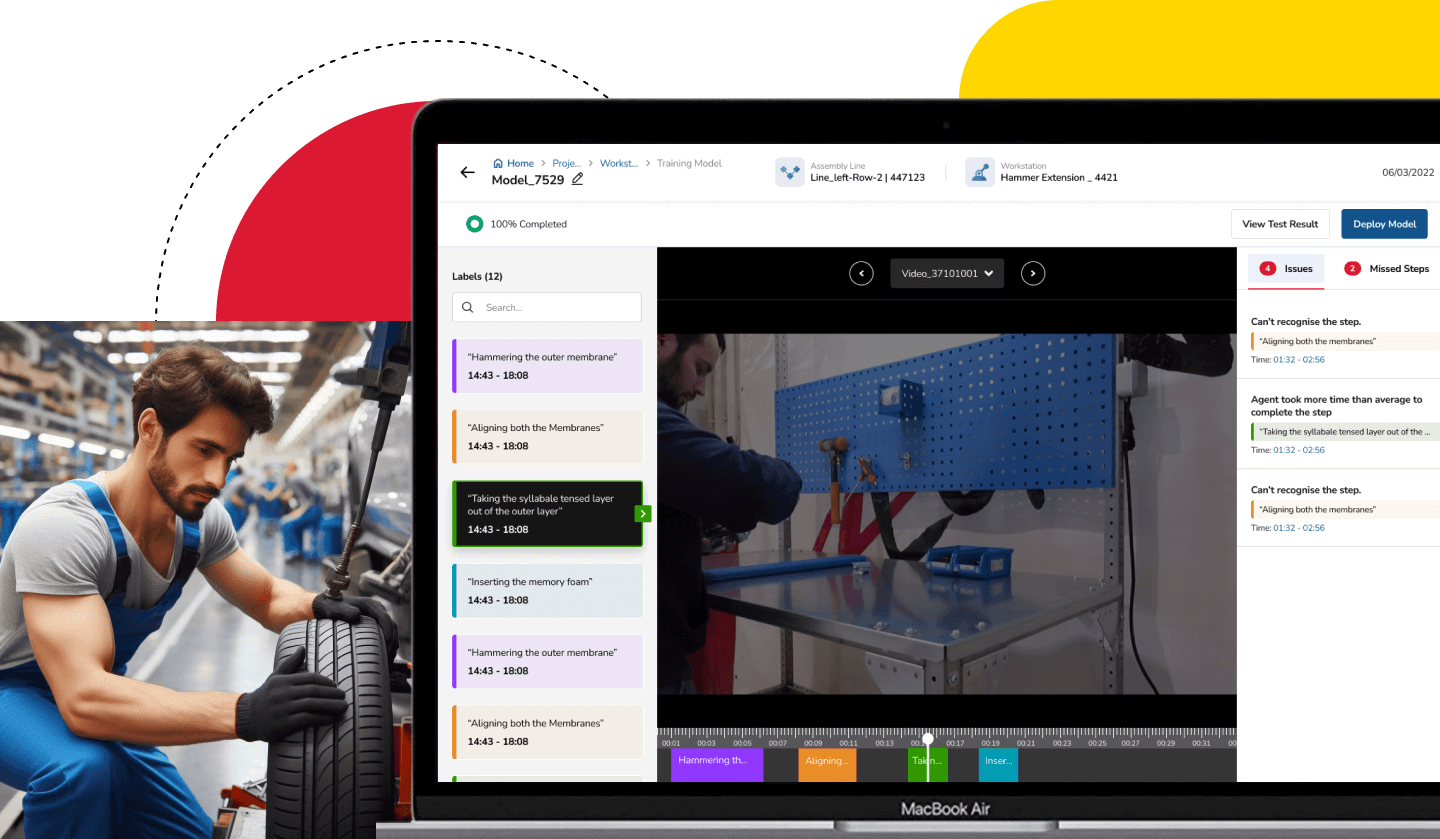

Video/Image/Agent Annotation

Empowering data understanding, mark by mark. Unlock insights with precision.

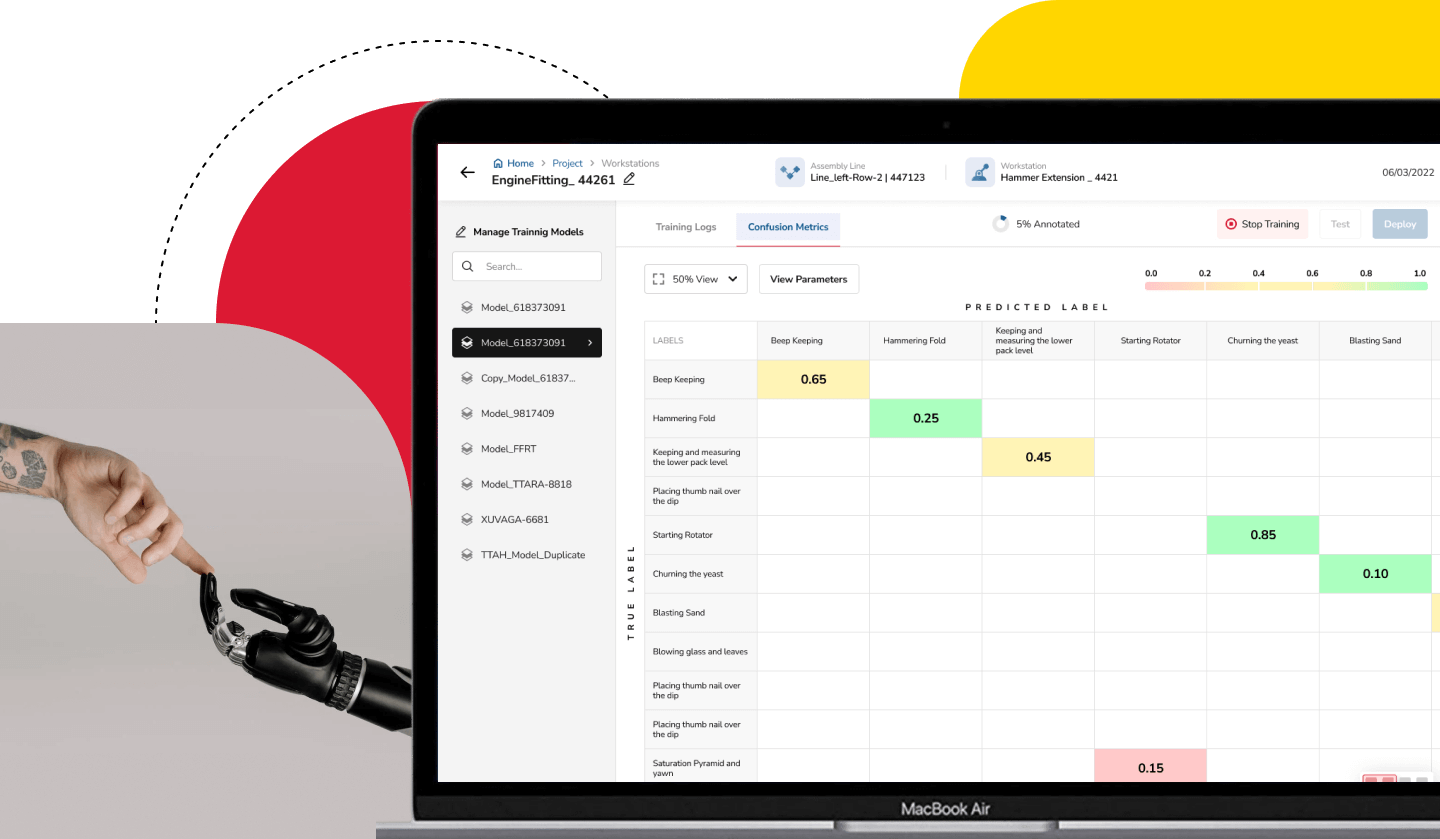

AI Confusion Metrics

Evaluating variation between human annotations and AI predictions for precise insights.

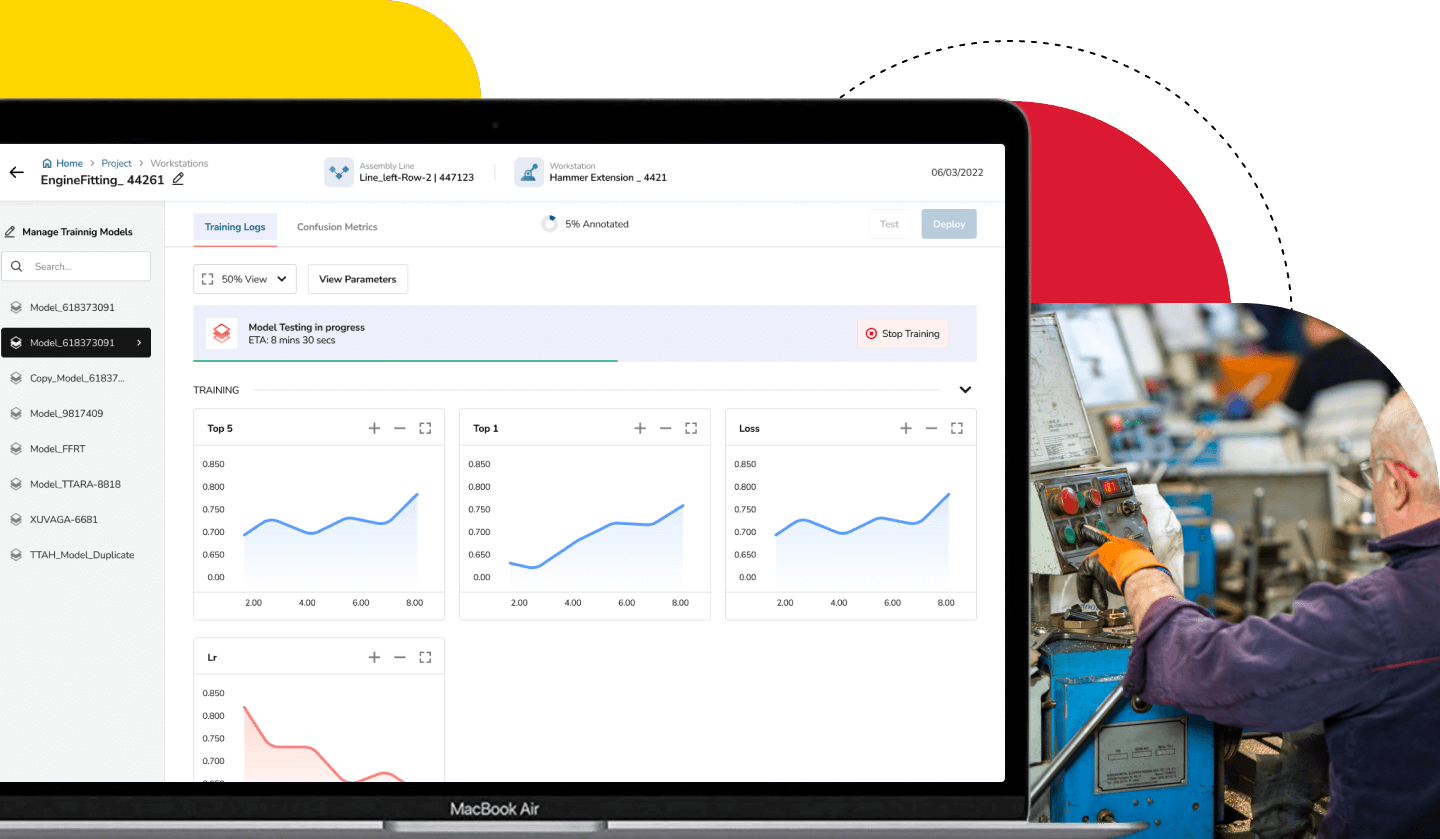

Model Training & Testing

Mastering every step for exceptional performance and reliability.

Training model results

Unleashing mechanical marvels: The triumphs of model training in precision engineering.

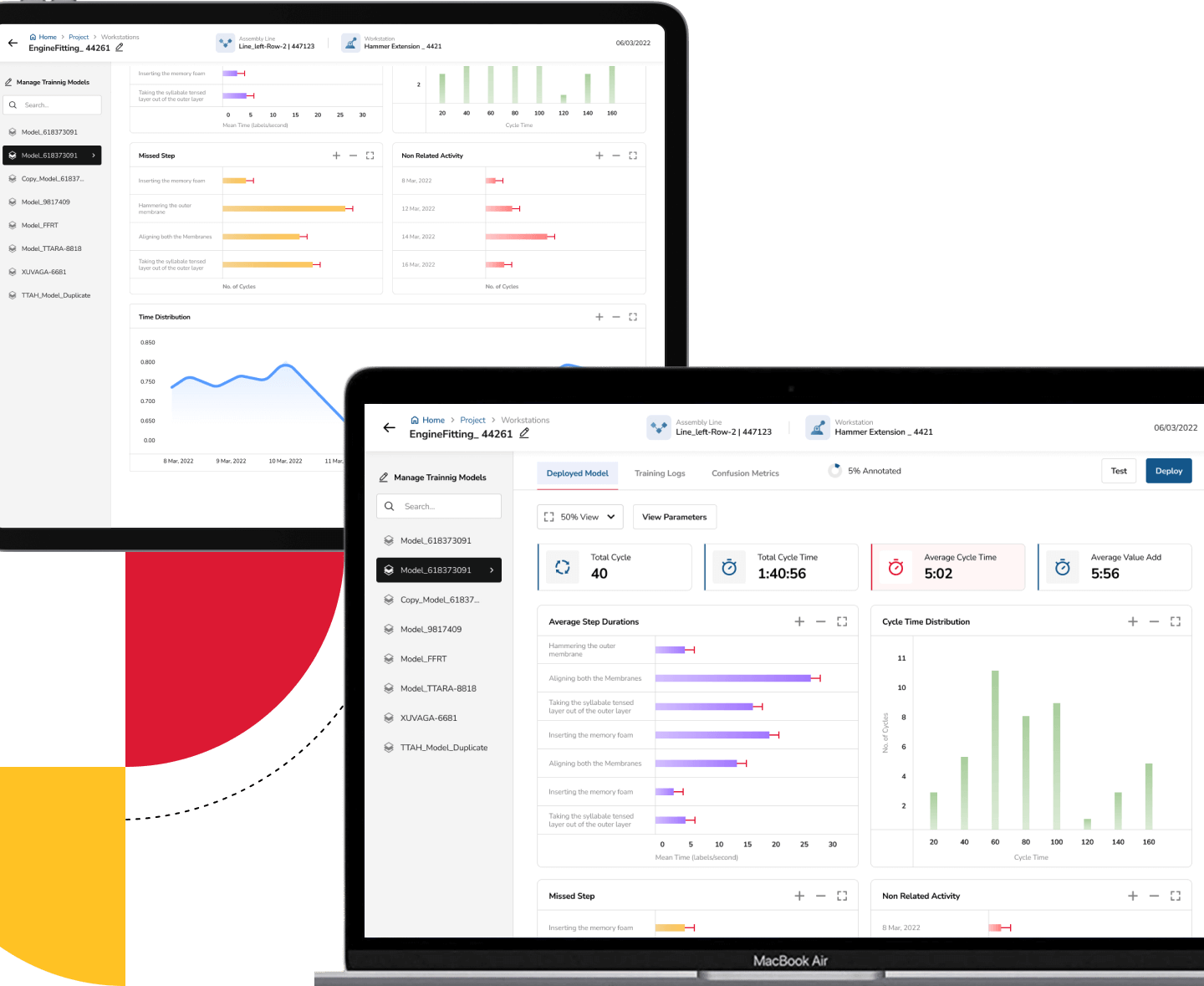

Deployed Model

Revolutionising the factory floor: Model deployment at the workstation.

Transforming Assembly Line Excellence

In the grand narrative of manufacturing, "LineSense" has emerged as the protagonist, reshaping the landscape of assembly line efficiency.

From the inception of data creation to the deployment of AI models on workstations, we've embarked on a journey that redefines precision in mechanical engineering.

DOMAIN LEARNINGS

With "LineSense," we've not only streamlined operations but also elevated product quality and reduced operational costs.

We stand at the crossroads of innovation, armed with scalability and adaptability, ready to write new chapters in manufacturing excellence.

The product is still under development and is going through a round of user testings. As they say...

Thank you for being a part of the "LineSense" story.